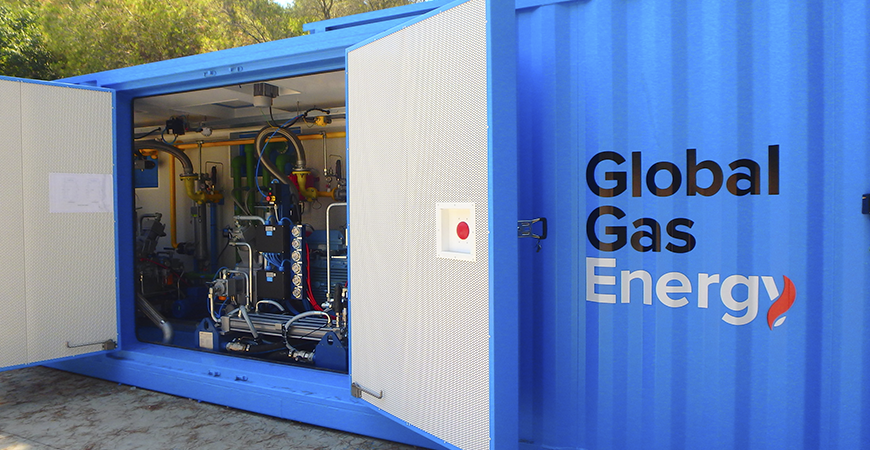

At Global Gas Energy (GGE) we have developed a the cooling system for gas installations. The CNG Cooling System is a system that has been designed for those filling processes of CNG transport systems that have problems with temperature during loading.

This system allows the temperature at which the gas enters the transport systems during the filling process to be reduced, with the result that at the end of the filling process the temperature inside is lower than if the system were not in place.

To explain what this system consists of we have to start from the fact that when a gas is compressed its temperature increases, that is to say, anything that is hotter will occupy more space than one that this cold.

In places like South America there is no gas pipeline network as we have in Europe, which is why when gas is to be supplied to an industry that wants to consume large quantities, but is far away from the network, the only way to be able to bring gas to them is by means of trucks.

When a CNG truck is filled, the gas is compressed and at the same time heated, and after several hours it cools down so that the capacity of the truck is not used at 100%.

With the cooling systems what is done is to lower the temperature of the gas before filling the transport trucks with gas, this way when the trucks are filled even though the temperature increases, as due to the initial temperature being lower the trucks end up be being up filled more. The system is always the same, an AIR-WATER cooling system is installed that lowers the water temperature to -5 or -15 ºC. This water is then passed through high pressure exchangers where the water cools the compressed gas to 250 bar. In a way that lowers the temperature.

Its application can be made on all those main stations that fill trucks with CNG to take them to decompress in subsidiary stations that have problems with the temperature when filling the trucks.

CNG Cooling System success stories:

All of them are main stations that in their day had problems with filling.

- Project in Peru (Talara): Gascop in 2013

- Project in Peru (Lima): Energicas en 2014

- Project in Colombia (Villavicencio): GNI in 2014

At Global Gas Energy we offer you the best solutions for gas industry equipment. Tell us your needs and we will develop the system that best fits your company.